OKM 500 Full Automatic Cartoning Machine

The OKM500 It is a Full Automatic Cartoning Machine that packs and sorts automatically one or more packages and fills them into desired arrangement. It automatically getting the carton from the magazine opening, getting the certain shape, closing the bottom flaps, then sealing by tape. The machine also has a vibration system to fit packaging, with automatic adjustment systems that make product and size changes simple and fast, as well as a weighing system that identifies and separates missing or overweight cartons.

TECHNICAL FEATURES OF OKM 500 FULL-AUTOMATIC CARTOONING MACHINE

Easy and understandable adjustment and usage possibility thanks to PLC-HMI Interface.

Possibility of using in short and narrow areas within packing lines thanks to its compact structure.

Cardboard box carrying magazine with chain system and easy cardboard box feeding possibility.

The advantage of existing empty package feeding magazine and filled package exit at the same place.

Using packing-line capacity in maximum level thanks to "Bobbin goes down" warning system.

Standstill-free working possibility thanks to reserved ready packet area between packet preparing

unit and filling unit.

Optional checkweigher in packet exit in order to control packet weight in gram.

The advantage of being packets in order within cardboard box by means of under-packet vibration system in cardboard box filling unit.

Fast passing possibility between different bale sizes thanks to formula system.

Easy in-cardboard box layout-type change thanks to counting and lining up features with servo-system.

Automatic bailing possibility of products coming out one or more packing machines.

Feature of easy integration with packing machines.

Electromagnetic safety switches complying with CE Standard in all doors.

Speed-controlled machine inlet conveyor.

ADVANTAGES OF FULL-AUTOMATIC BAILING SYSTEM

Saving is provided in labour costs thanks to full-automatic working system.

It ensures significant material cost advantage compared to cartooning which uses polyethylene packing material.

It decreases packing -line standstills caused from personnel to minimum level since it works as integrated with packing machines and ensures that packing lines work in maximum capacity.

It guarantees in-bail packet numbers thanks to automatic counting system.

It decreases packing-material costs since bail package is used as roll.

In-bail packets can easily be changed as single-row, double-row or triple-row from operator screen.

In-bail packet numbers or number s of layers being put on top of each other can easily be changed from operator screen.

In packet inlet conveyors, in-packet air can be evacuated in desired percentage and standard packing is made.

|

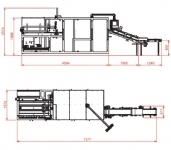

TECHNICAL DETAILS |

OKM 500 |

| Filling and Stacking System | Servo Counter and Distributor System |

| Packed product | All kind of packed products |

| Cartoning combinations & quantity | Depends of the product dimensions can be adjust |

| Cartoning / Infeed capacity | 10-12 Carton / minute 110-120 packs per minute infeed capacity |

| Carton Material | Single or double wavy corrugated |

| Width of Carton Package | Min. 120 mm. / Max. 280 mm |

| Height of Carton Package | Min. 120 mm. /. Max. 450 mm |

| Opened Carton Dimensions | min 540x330 mm. / Max.800x650 mm |

| Closed Carton Dimensions | Width Min. 200 * 300 mm Length Min.350 max. 350 mm |

| Carton heights | Min. 130 mm – max 400 mm |

| Cartons Storage Sizes | 140 cm |

| Dimensions of the Machine | 1570*4600*1980 mm |

| Weight of the Machine | 2.450 kg. |

| Pneumatic System | FESTO, SMC |

| Electric System | SIEMENS, OMRON |

| Power supply and consumption | 12 Kwh |

| Air supply and consumption | 6 Bar, 550 lt/dk. // 6 Bar, 550 lt/min. |